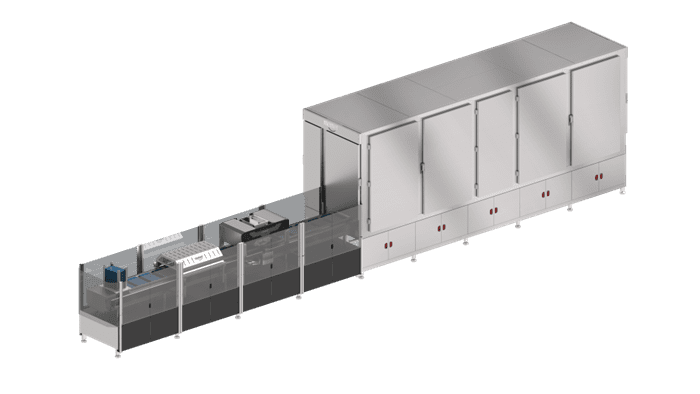

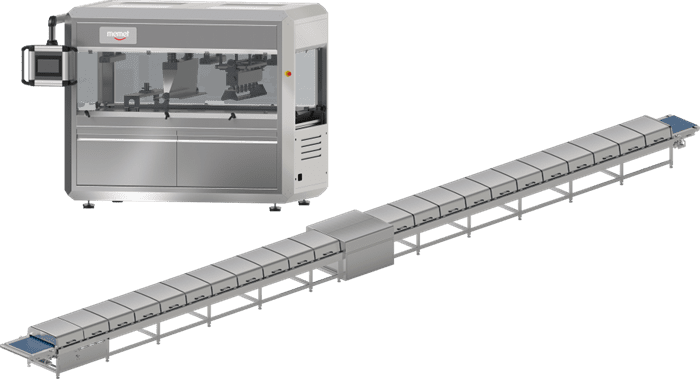

It has a wide range of applications like pralines, bars or baked goods etc. and has been developed to create the highest quality coatings. Appropriate coating thickness and permanent shine are its outstanding features. Chocolate, caramel and sugar masses as full and half coating are suitable for coating products, as well as bars, etc. Band width is 1000 mm and made of stainless steel. Every part of the machine that comes into contact with food is made of stainless hygienic material. Chocolate level runs in harmony with the tempering machine and can be monitored with sensors. The heating system inside the coating cabinet is equipped with ceramic heaters and the inside of the cabinet can be kept at the desired temperature.

COOLING TUNNEL

Thanks to its renewed modular design, it can be produced at the desired distance according to the needs of the product to be applied and the business. Thanks to two different cooling zones, the inlet-outlet cooling temperatures can be adjusted independently from each other at the desired value. Bidirectional openable covers and cabinet design provide optimum accessibility for cleaning and maintenance. All functions like belt speed, temperature, etc are easily controlled from the PLC panel with a user-friendly interface.

|

SERİ

|

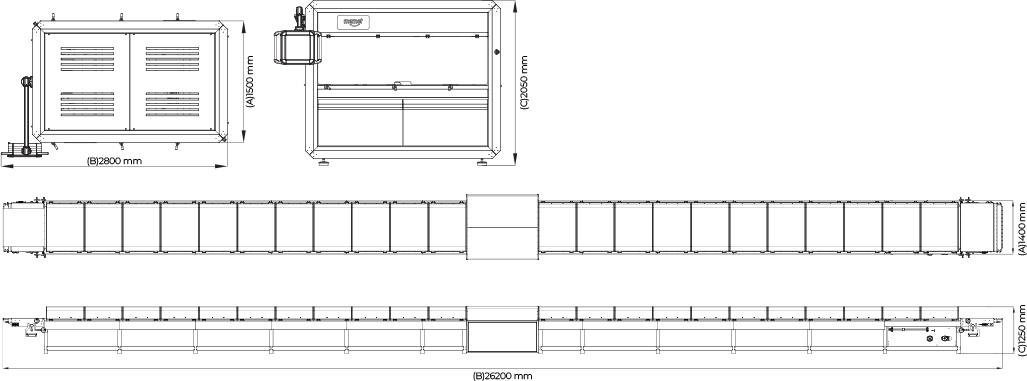

MMT-CK-1000

|

|

KAPASİTE

|

… кг/час

|

|

GÜÇ

|

12 kW / 380 V

|

|

GENİŞLİK

|

1500 mm MM

|

|

UZUNLUK

|

2800 mm MM

|

|

YÜKSEKLİK

|

2050 mm MM

|

|

AĞIRLIK

|

KG

|