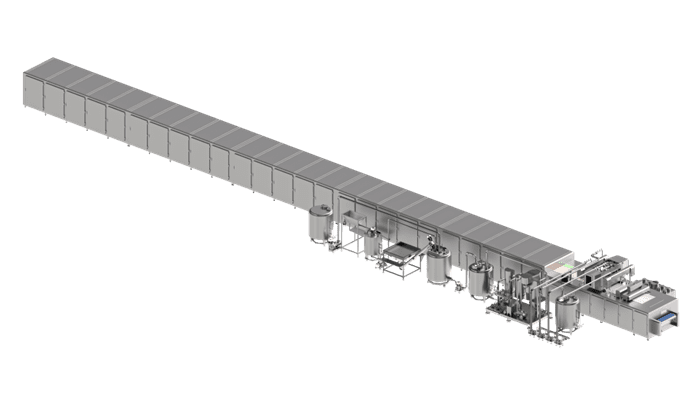

Compared to existing starchy production lines, it provides advantages through meeting minimum space requirement, less operator requirement and maximum hygiene standards. Silicone molds are used instead of starch molds for products which do not require drying, so it provides a more hygienic production process with lower production costs. Thanks to its redesigned servo-controlled filling system and high-efficiency cooling tunnel it has been developed to meet all the needs of mid-tier manufacturers, such as high production capacity and prod-uct-weight variety. All surfaces are designed with stainless steel and hygienic materials, so the produced products meet the highest standards and allow easy and practical cleaning. The body of the depositor has steam jacket and its temperature is fed by the steam unit. All functions of the line are easily controlled from the PLC panel having a user-friendly interface. It has a central continuous filling system. The cooling tunnel has 4 layers. There are 72 products in each mould.

|

Series

|

MMT-JLB-1000

|

|

Capacity

|

816 кг/час 42 форм/мин (4,5 г/изделие)

|

|

POWER

|

52 kW / 380 V

|

|

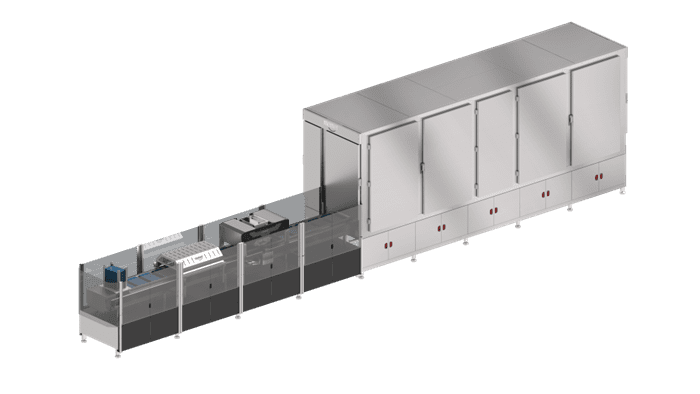

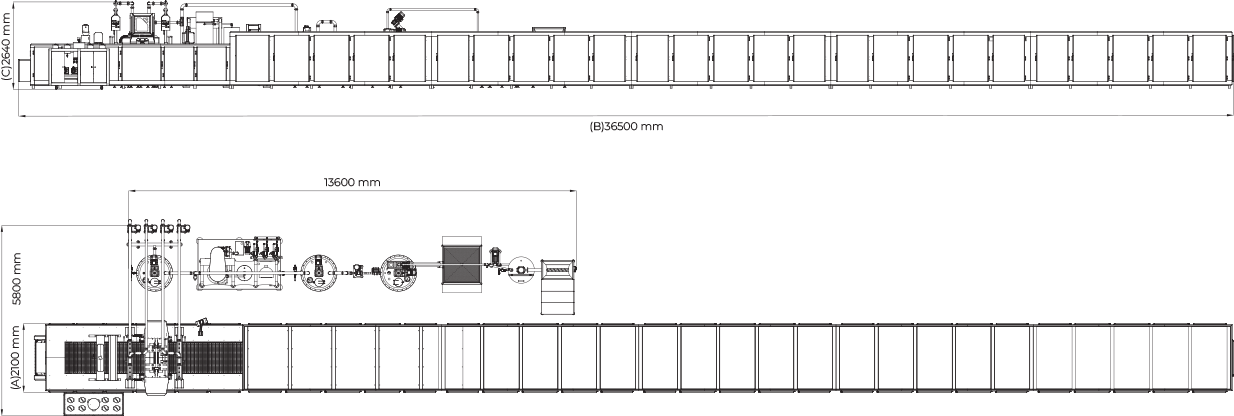

WIDTH

|

2100 mm MM

|

|

LENGTH

|

36500 mm MM

|

|

HEIGHT

|

2640 mm MM

|

|

WEIGHT

|

KG

|