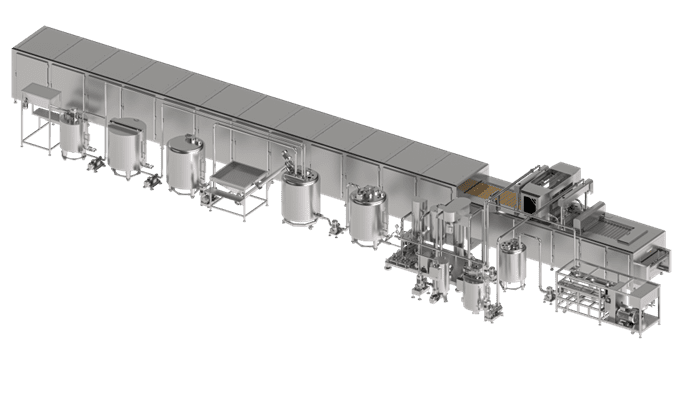

It has been developed to meet all the needs of the manufacturers, such as high production capacity and product-weight variety, thanks to its redesigned servo-controlled filling system and high-efficiency cooling tunnel. It provides a more hygienic production process besides low production costs. It provides the advantage of high efficiency production of your confectionery products like caramel, jelly, fondant etc...in a single line through meeting the changing needs of the customer in future. All surfaces are designed with stainless steel and hygienic materials; therefore, produced products meet the highest standards and easy and practical cleaning. The body of the depositor has steam jacket and its temperature is fed by the steam unit. All functions of the line are easily controlled from the PLC panel with a user-friendly interface. It has a central continuous filling system. The cooling tunnel has 4 layers. There are 42 products in each mold.

|

Series

|

MMT-KRM-1000

|

|

Capacity

|

600 кг/час 35 формы/мин

|

|

POWER

|

68 kW / 380 V

|

|

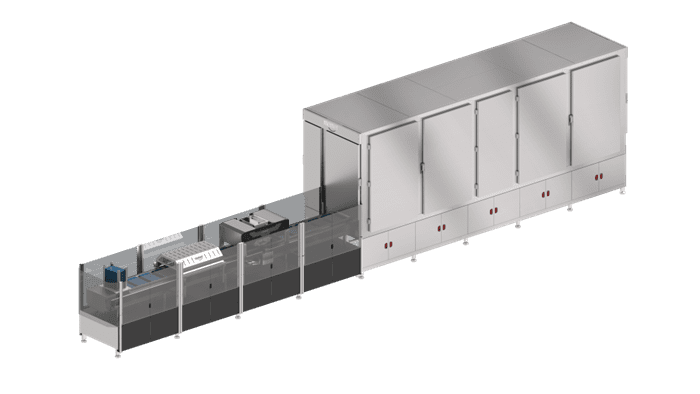

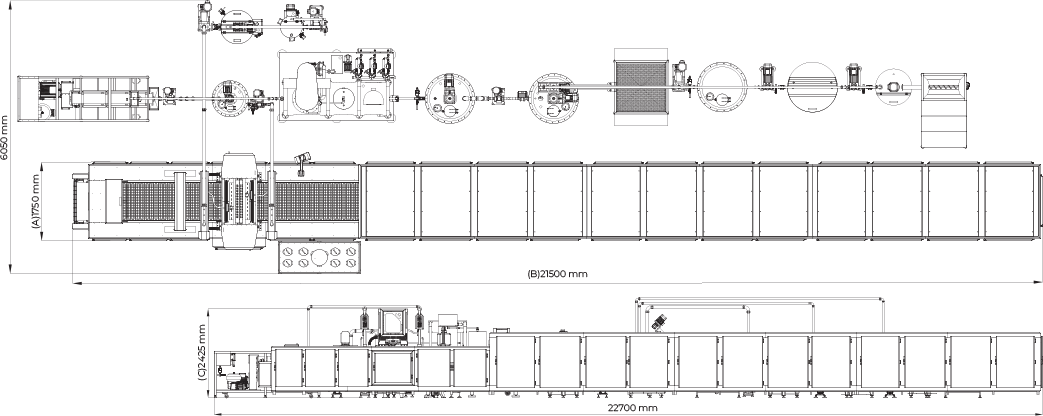

WIDTH

|

1750 mm MM

|

|

LENGTH

|

21500 mm MM

|

|

HEIGHT

|

2425 mm MM

|

|

WEIGHT

|

KG

|