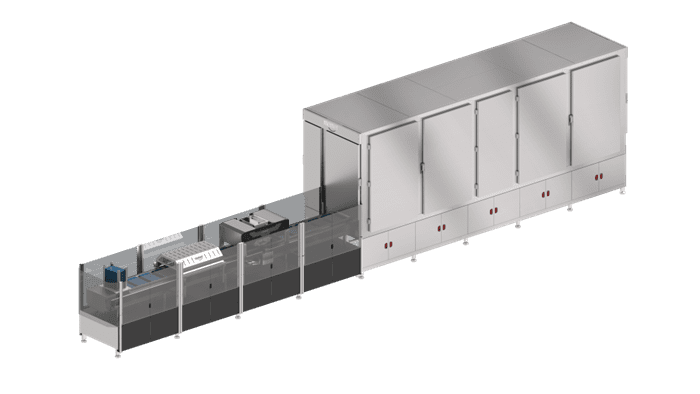

Thanks to its innovative design and easy-to-apply simplified units, it has been developed to meet all the needs of manufacturers who want to increase their productivity. Its modular and flexible structure ensures that the system is highly scalable and adaptable to the needs of the facility that will be installed. It provides a very economical and highly efficient production advantage for the products such as filled or unfilled chocolates, pralines, bars, tablets, etc. Optional Units such as Hazelnut Unit, Granule Pouring Unit, Biscuit Unit can be added for obtaining different products in the automatic Oneshot line. All functions of the line are easily controlled from the PLC panel having a user-friendly interface. All surfaces are designed with stainless steel and hygienic materials, so the produced products meet the highest standards and it allows easy and practical cleaning. The body of the depositor has a hot water jacket and its temperature is controlled by the external water tank unit. The cooling tunnel has 26 layers. It has a total cooling capacity of 400 moulds and the dwell time in the tunnel for each mold is 26.6 minutes.

|

Series

|

MMT-OS-A-900

|

|

Capacity

|

900 кг/час 13-16 форм/мин

|

|

POWER

|

35 kW / 380 V

|

|

WIDTH

|

4400 mm MM

|

|

LENGTH

|

18600 mm MM

|

|

HEIGHT

|

3250 mm MM

|

|

WEIGHT

|

KG

|